Ethylene oxide sterilization cabinets mainly use ethylene oxide gas to produce huge energy when decomposing under certain conditions in the sterilization chamber, which destroys the internal structure of bacteria, thus causing damage to bacteria and achieving sterilization effect.

Hysteroscope, laparoscope, laryngoscope, probe, rigid endoscope, hose endoscope, ophthalmic lens, fiber optic cable, cranial pressure sensor, cold therapy probe, prostatectomy device, esophageal dilator, electrocautery device, defibrillation electrode, laser head, metal, glass, silicone, rubber, human implants, etc.

1.Product form:Manual door vertical

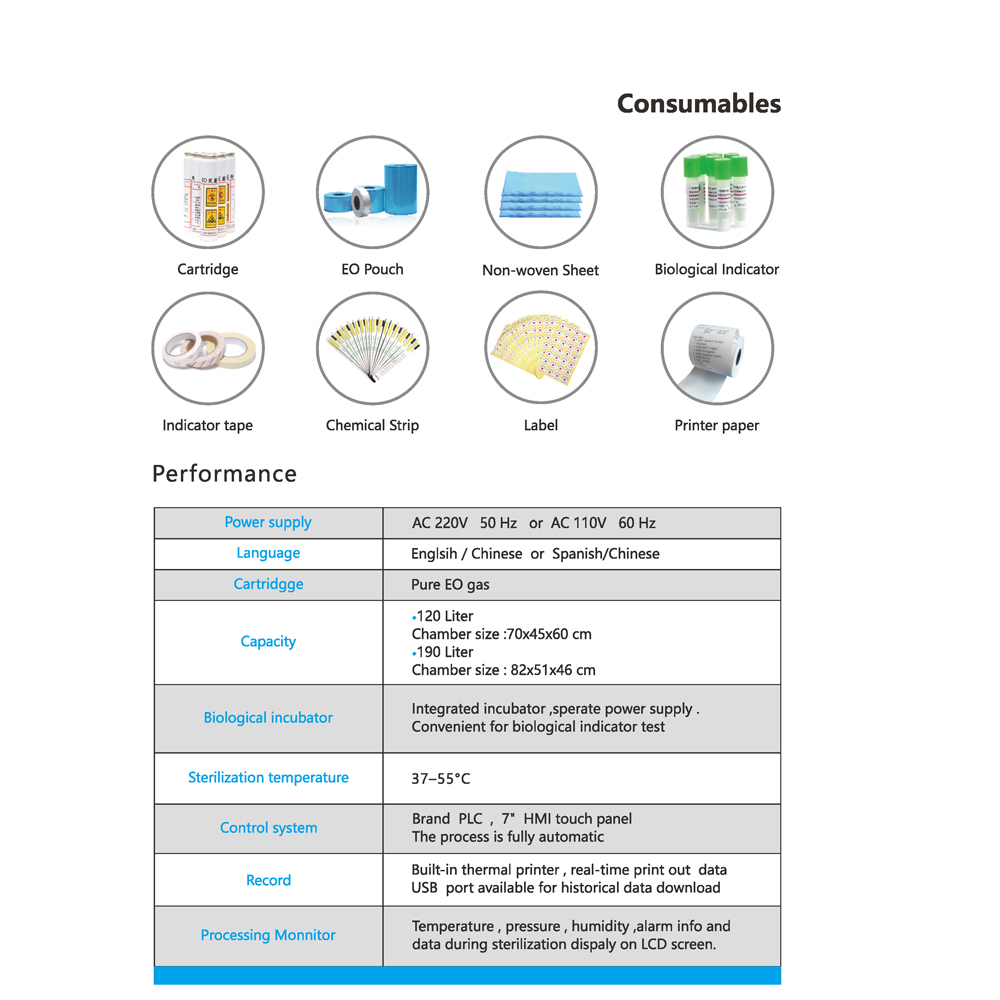

2.Heating mode: electric heating

3.Electricity source: AC220V 50Hz

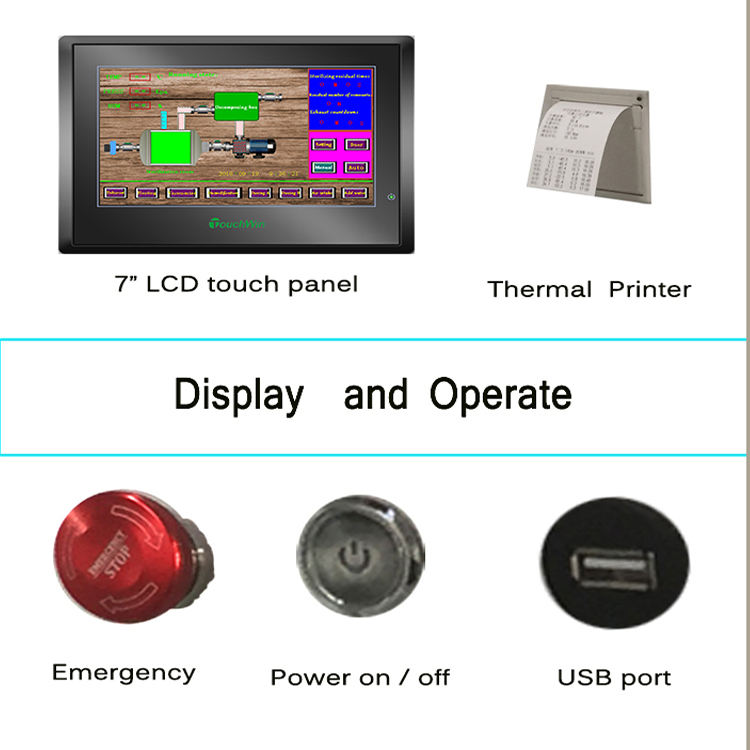

4.Indicator: LCD touch screen

5.Sterilization chamber material: 304 stainless steel

6.Outer box material: carbon steel (1.8mm thick) baked plastic powder

7.Gas selection: pure ethylene oxide gas

8.Sterilization time: 0-999 hours adjustable

9.Vacuum speed: -60kPa in 15 minutes

1.Control System :One-button start to finish, the whole process is done automatically.

2.Humidity Sensor:Built-in humidity sensor automatically detects the humidity in the chamber.

3.Pressure sensor:Built-in pressure sensor automatically detects the pressure inside the chamber.

4.Printer:Adopt a micro printer to print out the data during the whole sterilization process, which can be saved for a long time.

5.Display Status:Display the operation status, temperature, humidity, pressure, sterilization time, residual gas treatment time, times, and steam generator temperature.

6.Ethylene oxide sterilisation is known to be an effective gas sterilisation method with a wide range of sterilisation, strong penetration, no damage to items, no pollution of the environment, perfect, simple and reliable chemical detection and biological detection methods. The sterilised items are easy to preserve and other advantages, and are commonly used in hospitals as low temperature sterilisation and disinfection equipment.